Threaded Flanges Manufacturer, Supplier, and Exporter in India

Forcible Forge Industries, situated in Mumbai, India, stands as a premier manufacturer of Threaded Flanges. Our Threaded Flanges boast a high level of quality and are meticulously crafted to meet the diverse piping needs across various industries such as steel factories, chemical plants, petrochemical sectors, fire protection systems, and more. Our range encompasses a variety of Threaded Flanges including Monel, Inconel, Carbon Steel, Copper Nickel, Stainless Steel, and beyond. Each of our Threaded Flanges adheres strictly to international quality standards (IQS) during the design and development process. Additionally, we offer customized solutions tailored to our customers' specific requirements.

ASTM A182 Threaded Flanges Manufacturers, ASME B16.5 Threaded Flanges Suppliers, and A234 WPHY 42/WPHY Threaded Flanges Stockists in India

Forcible Forge Industries proudly holds the title of the world's leading manufacturer of Threaded Flanges. With clients spanning five continents and approximately 80 countries, we diligently cater to the vast global demand. Renowned for their reliability and quality, our Threaded Flanges enjoy a stellar reputation worldwide. We value our clients as partners, prioritizing their needs by delivering exceptional products and services. At Forcible Forge Industries, we produce Threaded Flanges in diverse shapes, sizes, and specifications, tailored precisely to our customers' preferences and requirements.

Threaded Flanges Specification, Grades, and Material

| Threaded Flanges | Specifications |

| Standards | ANSI, JIS, DIN, EN1092-1, UNI, BS4504, SABS1123, AS2129, GOST-12820 |

| Dimension | ANSI B 16.5 Threaded Flange, BS 1560. BS 10 Threaded Flange, IS 6392, B-2.1 NPT Threaded Flange, API Threaded Flange, DIN Threaded Flange, JIS. MSS SP 44 Threaded Flange |

| Material | ASTM A105 Threaded Flange, ASME A105 Threaded Flange ASTM A266 GR.1 Threaded Flange, GR.2 Threaded Flange, GR.3 Threaded Flange, GR.4 Threaded Flange ASTM A350 LF1 Threaded Flange, LF2 CL1/CL2 Threaded Flange, LF3 CL1/CL2 Threaded Flange ASTM A694 F42 Threaded Flange, F46 Threaded Flange, F48 Threaded Flange, F50 Threaded Flange, F52 Threaded Flange, F56 Threaded Flange, F60 Threaded Flange, F65 Threaded Flange, F70 Threaded Flange |

| Class | Threaded Flange 150#, Threaded Flange 300#, Threaded Flange 600#, Threaded Flange 900#, Threaded Flange 1500# & Threaded Flange 2500# |

| Size | 1/2” NB TO 24” NB. |

| Form | Threaded Flanges |

Grades |

|

| Stainless Steel | ASTM /ASME A/SA 213 / 249 / 269 / 312 / 358 CL. I to V – 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316TI , 316H , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H , 904L . |

| Duplex Steel | ASTM/ASME A/SA 789, 790 – UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Carbon Steel | ASTM A106 Gr. A , B & C API 5L Gr. A / B, X42 ,X52 ,X60 ASTM A 53 Gr. A/B |

| Alloys Steel | ASTM /ASME A/SA 213 / 335 / 691 – P5,P9,P11,P12,P22,P91 |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

About Threaded Flanges

Threaded flanges facilitate pipe connections without the need for welding. Similar to slip-on or socket weld flanges, they feature a tapered thread (screw) inside the flange bore that aligns with corresponding external threads on the pipe. In certain instances, a seal weld may also be applied in conjunction with threaded pipe flanges.

While threaded pipe flanges come in various dimensions, they are primarily utilized in small diameter pipelines, typically those below 4 inches in diameter. However, they are not suitable for pipe systems with thin wall thicknesses, as there is insufficient space to accommodate threading.

Threaded Flange Types

Two types of threaded flanges exist. One type seals the two pipe ends with a specific sealing surface and a lens pad, commonly employed in ammonia production. However, recent advancements have rendered this type less common, with the lens pad being replaced by a metal ring. Manufacturers and suppliers of threaded flanges are accessible globally.

The second type mirrors a standard flange, sealing with two flange sealing faces.

Facing Types

Threaded flanges are available in two facing types: ring joint flanges and raised face flanges.

Raised Face Threaded Flange

Raised face flanges can be easily identified when the gasket surface area extends above the bolted line of the flange. They are compatible with a wide range of gaskets, including flat, semi-metallic, and metallic types, available in both ring and full configurations.

The primary purpose of the raised face flange design is to concentrate the pressure of the two mating flanges on a small surface area, thereby enhancing the strength of the seal.

The height of the raised face surface varies depending on the flange pressure rating. For instance, for pressure classes 150 and 300, the height typically measures 1.6 mm or 1/16 inch, whereas for pressure classes ranging from 400 to 2500, the raised face height is approximately 6.4 mm or 1/4 inch.

RTJ Threaded Flange

The Ring Joint Flange features a circular groove designed to accommodate the ring joint gasket. This configuration is preferred for applications necessitating metal-to-metal seals, particularly under conditions of high pressure and high temperature.

Referred Standard and Grades

ASTM A105: Standard forged carbon steel pipes components for environmental and high temperature / high-pressure systems.

ASTM A182: The standard for alloy and stainless threaded flanges. Common Stainless steel grades: F304, 304/, F316, F316L, alloy grades: F5, F9, F11, F22, F91.

Convenient Installation and Maintenance

The threaded flange is attached to the threaded pipe via threading, which is machined into the inner hole of the flange. This eliminates the need for welding, making installation and maintenance considerably more convenient compared to other flange types like slip-on flanges or socket weld flanges.

Application in Special Circumstance

Threaded flanges find application in situations where welding is challenging or not feasible, such as when preserving the galvanized layer of a pipe. However, they should not be employed on pipes experiencing frequent temperature fluctuations or operating in extreme temperature conditions, specifically above 260°C or below -45°C.

According to the ASME B31.3 standard, when steel pipe is threaded and utilized for steam service above 250 psi or for water service above 100 psi with water temperatures exceeding 220°F, the pipe must be seamless and possess a thickness equivalent to at least schedule 80 of ASME B36.10.

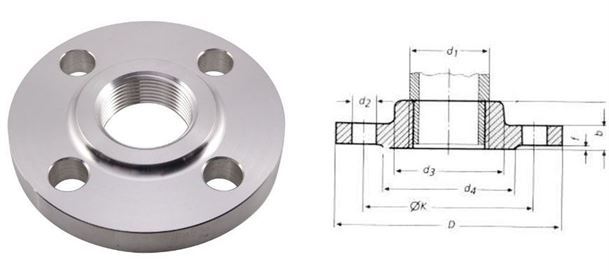

Measurement

If threaded pipe flange can be measured accurately, the following data shall be required:

O: Outside Diameter of flange

C: Thickness of flange

R: Diameter of raised face

X: Hub Diameter at base

Y: Length through the hub

T: Minimum thread length

Q: Minimum diameter of the bolt circle

Threaded Flanges Applications and Uses:

- Threaded Flanges used in Homes and buildings

- Threaded Flanges used in Transporting materials

- Threaded Flanges used in the Automotive industry

- Threaded Flanges used in Sewerage systems, industrial water lines, and water mains

- Threaded Flanges used in heating, ventilating, and air-conditioning equipment

- Threaded Flanges used in Plumbing

- Threaded Flanges used in Food Processing Industry

- Threaded Flanges used in Paper & Pulp Industry

Flanges Types

- Socket Weld Flanges

- Threaded Flanges

- Reducing Flanges

- Orifice Flanges

- Industrial Flanges

- Slip on Flanges

- Blind Flanges

- Lap Joint Flanges

- Ring Joint Flanges

- Spectacle Flanges

Forcible Forge Industries is a Leading Supplier of Threaded Flanges in India

Forcible Forge Industries stands as India’s most reputable manufacturer of Threaded Flanges. Our commitment to delivering high-quality products, coupled with exceptional customer service and in-house processing capabilities, has propelled us to become one of the foremost suppliers of Threaded Flanges in India. Since our establishment in 2004, Forcible Forge Industries has upheld ISO 9001:2009 certification, emphasizing our dedication to quality and excellence in Threaded Flanges manufacturing. Our unwavering focus on product reliability and performance has cemented our position as the premier choice among businesses, manufacturers, and suppliers of Threaded Flanges in India. For the best quality and service, trust Forcible Forge Industries as your leading Threaded Flanges Manufacturer in India.

Client Projects for Threaded Flange Supplier in India

Forcible Forge Industries holds a prestigious position as one of the premier Threaded Flanges Manufacturers in India. Monthly, we supply our Threaded Flanges products to approximately sixty countries, serving a diverse range of customers. Over the past two decades, our relentless commitment has seen us dispatch over 3500 containers of Threaded Flanges worldwide. Renowned for our reliability and quality, our brand signifies prompt delivery, competitive pricing, and superior Threaded Flanges. With a widespread presence, we have supplied Threaded Flanges to numerous cities across India, earning recognition as a leading manufacturer of Threaded Flanges worldwide. Trust in Forcible Forge Industries for exceptional Threaded Flanges solutions wherever you are.

| Product supplied | City |

| Threaded Flanges for Automobile Industry | Delhi, New Delhi |

| Threaded Flanges supply | Hyderabad, Telangana |

| Threaded Flanges supply for Water Supply System | Banglore, Karnataka |

| Threaded Flanges for Chemical industry | Surat, Gujarat |

Threaded Flanges Supplier in India

The reliability and performance of our Threaded Flanges have positioned Forcible Forge Industries as a leading manufacturer, supplier, dealer, and exporter of Threaded Flanges in India. Every month, we export around fifty-seven containers of Threaded Flanges to various Indian ports, catering to diverse clientele.

Thanks to our commitment to delivering high-quality Threaded Flanges at competitive prices, coupled with straightforward services, we have established sales representatives in key cities across India, including:

| City we supply Threaded Flanges | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Threaded Flanges Exporter

Forcible Forge Industries proudly exports Threaded Flanges to over 50 countries worldwide. With monthly shipments to various destinations for our growing customer base, our extensive ready stock of Threaded Flanges enables us to promptly fulfill orders and meet the diverse requirements of our clientele. In addition to our existing customer base, we also extend our Threaded Flanges offerings to other countries, ensuring our products reach customers globally.

| Countries we supply and export Threaded Flanges worldwide | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | New Zealand |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

Threaded Flanges Packaging & Delivery Details

1. Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer), other

2. Port of Dispatch: Mumbai OR KALAMBOLI India

3. Packaging Details: Blind Flanges are packaged with caution and safety so they reach our client’s as good as he would expect. Packaging Charges Extra

4. Tax: 18% GST