Slip On Flanges Manufacturers, Supplier and Exporter in India

Forcible Forge Industries stands as a leading manufacturer of Slip On Flanges in Mumbai, India. Our comprehensive range of Slip On Flanges is meticulously crafted to cater to various piping applications across industries such as steel factories, chemical industries, petrochemical industry, fire protection systems, and more. Our diverse selection of Slip On Flanges includes Monel, Inconel, Carbon Steel, Copper Nickel, Stainless Steel, and more, catering to a wide spectrum of requirements. Each Slip On Flange is designed and developed in strict accordance with International Quality Standards (IQS), ensuring exceptional quality and reliability. Additionally, we offer customized Slip On Flanges tailored to meet the specific requirements of our customers.

ANSI B 16.5 Slip on Flange, BS 1560. BS 10 Slip on Flange, IS 6392 Slip on Flange, B-2.1 NPT Slip on Flange, API Slip on Flange in India

Forcible Forge Industries proudly leads as the world leader in Slip On Flanges manufacturing. Our reach spans across 5 continents and approximately 80 countries, serving a vast global clientele. Renowned worldwide for their reliability and quality, our Slip On Flanges are held in high regard across diverse industries. We prioritize our clients as partners, delivering top-notch products and services to meet their needs. Forcible Forge Industries manufactures Slip On Flanges in various shapes, sizes, and specifications, tailored precisely to our customers' requirements, solidifying our position as an industry leader.

Slip On Flanges Specification, Grades, and Material

| Slip On Flanges | Specifications | |||

|---|---|---|---|---|

| Standards | ANSI, JIS, DIN, EN1092-1, UNI, BS4504, SABS1123, AS2129, GOST-12820 | |||

| Dimension | ANSI B 16.5 Slip on Flange, BS 1560. BS 10 Slip on Flange, IS 6392 Slip on Flange, B-2.1 NPT Slip on Flange, API Slip on Flange, DIN Slip on Flange, JIS. MSS SP 44 Slip on Flange | |||

| Material | ASTM A105 Slip on Flange, ASME A105 Slip on Flange ASTM A266 GR.1 Slip on Flange, GR.2 Slip on Flange, GR.3 Slip on Flange, GR.4 Slip on Flange ASTM A350 LF1 Slip on Flange, LF2 CL1/CL2 Slip on Flange, LF3 CL1/CL2 Slip on Flange ASTM A694 F42 Slip on Flange, F46 Slip on Flange, F48 Slip on Flange, F50 Slip on Flange, F52 Slip on Flange, F56 Slip on Flange, F60 Slip on Flange, F65 Slip on Flange, F70 Slip on Flange |

|||

| Slip on Flange Class | Slip on Flange 150#, Slip on Flange 300#, Slip on Flange 600#, Slip on Flange 900#, Slip on Flange 1500# & Slip on Flange 2500# | |||

| Slip on Flange Size | 1/2” NB TO 24” NB. | |||

| Slip on Flange Form | Slip on Flanges – SORF | |||

Grades |

||||

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L | |||

| Super Duplex Steel | S32750 | |||

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. | |||

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 | |||

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. | |||

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 | |||

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI | |||

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L | |||

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G | |||

| Molybdenum | ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91, ASTM B387, Ferro Molybdenum | |||

| Cobalt | Cobalt HS-6, Cobalt HS-4, Cobalt HS-25, Sterlite Grade 1, Sterlite Grade 6, Sterlite Grade 12, Sterlite Grade 21 | |||

| Niobium | ASTM B394, R04200 R04210 | |||

| Nimonic | Nimonic75, Nimonic80, Nimonic85, Nimonic90, Nimonic263, etc | |||

| Tungsten | W1 WAl1, W61, etc, Carbonide Tungsten, Copper Tungsten, Nickel Tungsten | |||

| Nichrome | Nichrome90, Nichrome80, Nichrome80A, Nichrome RW80, Nichrome75, etc | |||

| Magnesium | Magnesium AL017100, AL017140, AL017150, AL017160, AL017200, AL017210, AL017250, etc. | |||

| Tantalum | Tantalum – Grade 1. | |||

| Monel | Monel 400, Monel k500 | |||

| MU-METAL | MU-METAL | |||

| Zirconium | Zirconium 702, Zirconium 705, Zirconium 705, Zirconium-2, Zirconium-4 | |||

| Beryllium Copper | Alloy 25 UNSC17200 | |||

| Aluminium | 1050,1100, 2017, 7150, 7178, 7575, 2050, 7085, 2011 A92011, 2014A A92014, 2024 A92024, 2219, 5052 A95052, 5083 A95083, 5754, 6061 A96061 A86061, 6063, 6082 A96082, 7071 7020, 7050 A97050, 7075 A97075 A87075, 7175 | |||

| Copper Alloys | C 11000, C 10200, C 12200, C 51100, C 51000, C 51900, C 52000, C 52100, C 74500, C 75700, C 75400, C 76400, C 77000, C 21000, C 22000, C 23000, C 24000, C 26000, C 26800, C 27000, C 27200, C 28000 | |||

About Slip On Flanges

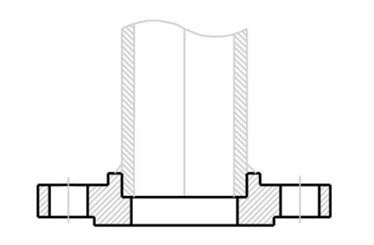

A Slip On flange, commonly known as SO flange, is a type of flange designed to slide over a pipe, featuring an internal diameter slightly larger than the pipe. This allows the flange to fit snugly over the pipe. With its inner diameter typically larger than the outer diameter of the pipe, the Slip On flange can be directly connected to equipment or pipe by fillet welds at the top and bottom of the flange. Its primary function is to insert the pipe into the inner hole of the flange, providing a secure and reliable connection.

Types of Slip On Flange Welding

The Slip On flange can be categorized into two main types: Slip On welding plate flange and Slip On welding neck steel pipe flange. These flanges possess mechanical characteristics that lie between those of lap joint flanges and integral flanges. Their basic structure and convenient processing make Slip On flange welding widely utilized in various fluid pipelines.

Additionally, depending on the specific requirements, Slip On flanges can feature different face types. These include ring type joint face types and raised face types, offering versatility and adaptability to various piping applications.

Raised Face Slip On Flange

The raised face slip on flange features a small protrusion from the bottom face of the flange. This raised portion serves as a seat for placing a gasket during installation, enhancing sealing performance. As pressure ratings increase, the height of this raised face also increases accordingly. This adjustment ensures optimal sealing and performance under varying pressure conditions.

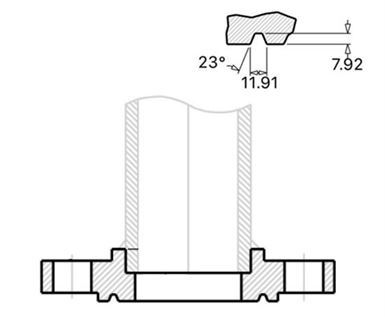

RTJ Slip on Flange

On the raised face part of the slip-on flange, a small groove is machined, creating what is known as the Ring Type Joint type. This groove serves as a seat for placing the gasket ring, which is crucial for sealing. Unlike the Raised Face type, the Ring Type Joint is specifically designed for high-pressure applications. Its robust design and gasket configuration make it ideal for withstanding elevated pressures while maintaining a reliable seal.

Slip on flange use slip welding to connecting equipment, so either below of name is describing the same flange:

- Slip on weld flange

- Slip on flange weld

- Weld slip on flange

- Slip on flange welding

- SO

Referred Standard and Grades

- ASTM A105 for carbon steel slip on pipe flanges

- ASTM A182 for alloy and stainless slip on flanges. (Alloy for F11, F22, stainless for F304/F304L, F316/F316L)

- ASME B16.5 for pipe flanges and flanged fittings

- BS 3293

- DIN 86029

Dimensions and Pressure Ratings

- Common outer diameters: 1/2”, 2”, 3”, 4”, 6”, 8”, 10”, 12”, to 24”

- Special made outer diameters: Up to 60”

- Class range: Class 150, Class 300, 400, 600, 900, 1500, 2500(# or LB). PN 2.5 to PN 250

- Flange face type: RF (Raised Face), RTJ (Ring Type Joint)

Manufacturing Types

Slip on flanges can be manufactured using various methods, including casting, forging, steel cutting, and more. Among these manufacturing methods, forging stands out for its excellent quality. However, it's worth noting that forged slip on flanges typically come at a higher price compared to those made using other methods. Therefore, before making a purchase, it's essential to consider the specific working environment in which the slip on flange will be used. Factors such as pressure, temperature, and corrosion resistance requirements should be carefully evaluated to ensure the appropriate selection of the flange type and manufacturing method that best suits the application.

Advantages of Slip On Flange

- Lower installation costs

- Easier to align with other parts during installation

- Better leaking proof

- Inner and outer welding on the flange

- Takes less time to cut accurately for the pipelines

- As pipe slides on the flange, it compatible with a lower hub on slip on flange

Slip On Flange vs Weld Neck Flange

The Slip On Flange exhibits certain characteristics and considerations that distinguish it from other types, such as the Weld Neck Flange:

1. Strength: The internal pressure strength of a Slip On Flange is typically around 2/3 of that of a Weld Neck Flange.

2. Durability: The durability life of a Slip On Flange is generally around 1/3 of that of a Weld Neck Flange.

3. Welding: Slip On Flanges require two fillet welds, one inside and one outside of the flange.

4. Space Requirement: Space needs to be allocated between the end of the pipe and the end of the flange during welding to prevent damage to the flange face.

5. Fitting Connection: The pipe must first connect with the Slip On Flange before connecting a fitting, as combinations like flange+tee or flange+elbow are not feasible due to fitting size constraints.

6. Cost: Slip On Flanges are typically cheaper than Weld Neck Flanges, making them a preferred choice for many clients.

7. Application: Slip On Flanges are commonly used in medium temperature piping systems with low pressure.

8. Welding Work: Since the pipe diameter is smaller than the flange bore, Slip On Flanges often require more welding work compared to other flange types, resulting in shorter installation durations.

Slip On Flanges Applications and Uses:

- Slip On Flanges used in Homes and buildings

- Slip On Flanges used in Transporting materials

- Slip On Flanges used in the Automotive industry

- Slip On Flanges used in Sewerage systems, industrial water lines, and water mains

- Slip On Flanges used in heating, ventilating, and air-conditioning equipment

- Slip On Flanges used in Plumbing

- Slip On Flanges used in Food Processing Industry

- Slip On Flanges used in Paper & Pulp Industry

Flanges Types

- Socket Weld Flanges

- Threaded Flanges

- Reducing Flanges

- Orifice Flanges

- Industrial Flanges

- Slip on Flanges

- Blind Flanges

- Lap Joint Flanges

- Ring Joint Flanges

- Spectacle Flanges

Forcible Forge Industries is a Leading Supplier of Slip On Flanges in India

Forcible Forge Industries stands out as India’s most trusted Slip On Flanges Supplier, renowned for our commitment to high-quality products, attentive customer service, and comprehensive in-house processing capabilities. Over the years, we have emerged as a leading supplier of Slip On Flanges in India, thanks to our dedication to excellence.

As an ISO 9001:2009 certified company established in 2004, Forcible Forge Industries prioritizes product dependability and performance, earning us a stellar reputation among businesses, manufacturers, and suppliers alike. Our relentless pursuit of quality ensures that our Slip On Flanges meet the highest standards, making us the preferred choice for customers across India.

Client Projects for Slip On Flange Supplier in India

Forcible Forge Industries is esteemed as one of the premier Slip On Flanges Dealers in India, catering to a vast clientele spanning approximately sixty countries worldwide. Over the past two decades, we have facilitated the delivery of over 3500 containers of Slip On Flanges to destinations across the globe. Renowned for our trusted brand name, we are synonymous with fast delivery, competitive pricing, and unparalleled quality of Slip On Flanges.

Our unwavering commitment to customer satisfaction has solidified our reputation as a trusted name in the industry. With a wide distribution network, we have successfully supplied Slip On Flanges to numerous cities across India, ensuring that our products reach customers wherever they are needed.

| Product supplied | City |

| Slip On Flanges for Automobile Industry | Delhi, New Delhi |

| Slip On Flanges supply | Hyderabad, Telangana |

| Slip On Flanges supply for Water Supply System | Banglore, Karnataka |

| Slip On Flanges for Chemical industry | Surat, Gujarat |

Slip On Flanges Packaging & Delivery Details

1. Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer), Other

2. Port of Dispatch: Mumbai OR KALAMBOLI India

3. Packaging Details: Slip On Flanges are packaged with caution and safety so they reach our client’s as good as he would expect. Packaging Charges Extra

4. Tax: 18% GST

Slip On Flanges Supplier in India

The reliability and performance of our Slip On Flanges have established Forcible Forge Industries as a leading supplier, dealer, manufacturer, and exporter of Slip On Flanges in India. Each month, we consistently supply/export approximately fifty-seven containers of Slip On Flanges to various Indian ports, serving diverse customers.

Our commitment to delivering high-quality Slip On Flanges at competitive prices, coupled with streamlined services, has been instrumental in our success. To better serve our customers, we have sales representatives stationed in key cities across India, including: [List of cities]. These representatives ensure efficient communication and support, further enhancing our ability to meet the needs of our valued clientele.

| City we supply Slip On Flanges | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Slip On Flanges Exporter

Forcible Forge Industries proudly exports Slip On Flanges to over 50 countries worldwide. With shipments dispatched monthly to cater to our expanding customer base, we ensure prompt delivery to meet their demands. Our extensive ready stock of Slip On Flanges enables us to swiftly fulfill orders and address customer requirements with efficiency.

In addition to our regular exports, we also offer Slip On Flanges to other countries, ensuring that our high-quality products reach customers globally. With our commitment to excellence and customer satisfaction, we strive to be a trusted partner for Slip On Flange solutions worldwide.

| Countries we supply and export Slip On Flanges worldwide | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | New Zealand |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |