Blind Flanges Manufacturers, Supplier and Exporter in India

Forcible Forge Industries stands as a leading manufacturer of Blind Flanges in Mumbai, India. Our comprehensive range of Blind Flanges is meticulously crafted to cater to various piping applications across industries such as steel factories, chemical industries, petrochemical industry, fire protection systems, and more. With diverse types including Monel, Inconel, Carbon Steel, Copper Nickel, Stainless Steel, and more, our Blind Flanges are designed and developed in strict accordance with International Quality Standards (IQS), ensuring exceptional quality and reliability. Additionally, we offer customized Blind Flanges tailored to meet the specific requirements of our customers.

Blind Flanges Manufacturers, Spectacle Blind flange, Tapped Blind Flange, Blind Pipe Flanges, Flat Face Blind Flange, and Blind Flanges Stockists in India

Forcible Forge Industries proudly leads as the world leader in Blind Flanges Manufacturing. With clients spanning across 5 continents and approximately 80 countries, we cater to a vast global demand. Renowned for their reliability and quality, our Blind Flanges are held in high regard worldwide. We prioritize our clients as partners, delivering top-notch products and services to meet their needs. Forcible Forge Industries manufactures Blind Flanges in various shapes, sizes, and specifications, tailored precisely to our customers' requirements, solidifying our position as an industry leader.

Blind Flanges Specification, Grades, and Material

| Blind Flanges | Specifications |

|---|---|

| Standards | ANSI, JIS, DIN, EN1092-1, UNI, BS4504, SABS1123, AS2129, GOST-12820 |

| Dimension | ANSI B 16.5 Blind Flange, BS 1560. BS 10 Blind Flange, IS 6392 Blind Flange, B-2.1 NPT Blind Flange, API Blind Flange, DIN Blind Flange, JIS. MSS SP 44 Blind Flange |

| Material | ASTM A105 Blind Flange, ASME A105 Blind Flange ASTM A266 GR.1 Blind Flange, GR.2 Blind Flange, GR.3 Blind Flange, GR.4 Blind Flange ASTM A350 LF1 Blind Flange, LF2 CL1/CL2 Blind Flange, LF3 CL1/CL2 Blind Flange ASTM A694 F42 Blind Flange, F46 Blind Flange, F48 Blind Flange, F50 Blind Flange, F52 Blind Flange, F56 Blind Flange, F60 Blind Flange, F65 Blind Flange, F70 Blind Flange |

| Class | Blind Flange 150#, Blind Flange 300#, Blind Flange 600#, Blind Flange 900#, Blind Flange 1500# & Blind Flange 2500# |

| Size | 1/2” NB TO 24” NB. |

Grades |

|

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L |

| Super Duplex Steel | S32750 |

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 |

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Molybdenum | ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91, ASTM B387, Ferro Molybdenum |

| Cobalt | Cobalt HS-6, Cobalt HS-4, Cobalt HS-25, Sterlite Grade 1, Sterlite Grade 6, Sterlite Grade 12, Sterlite Grade 21 |

| Niobium | ASTM B394, R04200 R04210 |

| Nimonic | Nimonic75, Nimonic80, Nimonic85, Nimonic90, Nimonic263, etc |

| Tungsten | W1 WAl1, W61, etc, Carbonide Tungsten, Copper Tungsten, Nickel Tungsten |

| Nichrome | Nichrome90, Nichrome80, Nichrome80A, Nichrome RW80, Nichrome75, etc |

| Magnesium | Magnesium AL017100, AL017140, AL017150, AL017160, AL017200, AL017210, AL017250, etc. |

| Tantalum | Tantalum – Grade 1. |

| Monel | Monel 400, Monel k500 |

| MU-METAL | MU-METAL |

| Zirconium | Zirconium 702, Zirconium 705,Zirconium 705, Zirconium-2, Zirconium-4 |

| Beryllium Copper | Alloy 25 UNSC17200 |

| Aluminium | 1050,1100, 2017, 7150, 7178, 7575, 2050, 7085, 2011 A92011, 2014A A92014, 2024 A92024, 2219, 5052 A95052, 5083 A95083, 5754, 6061 A96061 A86061, 6063, 6082 A96082, 7071 7020, 7050 A97050, 7075 A97075 A87075, 7175 |

| Copper Alloys | C 11000, C 10200, C 12200, C 51100, C 51000, C 51900, C 52000, C 52100, C 74500, C 75700, C 75400, C 76400, C 77000, C 21000, C 22000, C 23000, C 24000, C 26000, C 26800, C 27000, C 27200, C 28000 |

About Blind Flanges

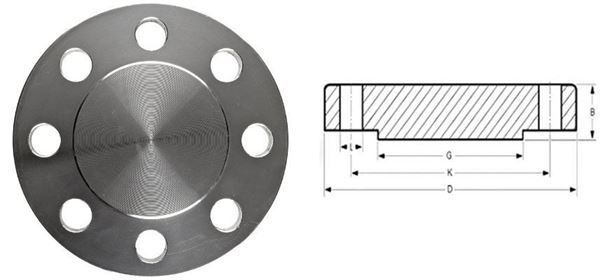

A blind flange, also known as a blind disk or flanged pipe plug, serves to seal the end of a pipe. Unlike other flanges, it lacks holes in the center, functioning similarly to a pipe cap or plug. Its detachable nature allows for easy replacement or maintenance, distinguishing it from other flange types.

The primary function of a blind flange is to completely isolate the production medium, preventing any flow through the pipe opening. This is crucial for preventing production disruptions, avoiding accidents, and ensuring safety. Blind flanges are typically used at equipment nozzles, between two flanges, or on either side of shut-off valves.

Depending on the specific application, different types of blind flanges may be used. For instance, a figure 8 blind flange (figure-8 blank) is recommended for locations requiring isolation between flanges or shut-off valves, while a common round blind flange is suitable for single-use parts such as purging or testing.

Blind flanges feature various sealing surfaces, including flat, grooved, concave, convex, and ring joint surfaces, each suited for different sealing requirements and applications.

Material Types and Standards

Materials of Blind Flange usually required in stainless steel, carbon steel, aluminum, alloy steel, copper, and etc.

- Carbon steel blind flange: ASTM A105

- Alloy steel: ASTM A182 F5, F9, F11, F22, F91

- Stainless steel blind flange: ASTM A182 F304/L, F316/L

Manufacturing Standards

- ASME B16.5

- BS 3293

- DIN 86029

Dimensions

- General use OD range: 1/2”, 2”, 3”, 4”, 6”, 8”, 10”, 12”, to 24”

- Special made OD: Up to 60”

- Class range: Class 150, Class 300, 400, 600, 900, 1500, 2500

- Flange face type: RF (Raised Face), RTJ (Ring Type Joint)

Manufacturing Types and Costs

Generally, there are four types of manufacturing processes: casting, forging, medium plate cutting, and casting and forging. Among these, forging typically commands the highest price, followed by medium plate cutting, with casting and forging being the most economical. However, casting is generally considered inferior compared to the other methods. In terms of quality, forging and medium plate cutting are regarded as the best, followed by casting and finally casting and forging, which may exhibit slightly lower quality.

Casting Blind Flange

The casting flange blank boasts precise shaping, low processing requirements, and cost-effectiveness. However, it is prone to casting defects such as air holes, cracks, and inclusions. Additionally, the internal casting part may have poor streamline characteristics, especially if it's a cutting component, where the streamline is further compromised.

Forging Blind Flange

Forged blind flanges generally feature lower carbon content compared to cast flanges, making them less susceptible to rust. Furthermore, forgings exhibit a denser structure, superior streamlined shape, and enhanced mechanical properties compared to cast flanges. However, improper forging methods can result in larger or uneven grain structure and may lead to hardening cracks. Despite these advantages, casting flanges typically incur lower costs compared to forging.

Precautions When Use

Ensure that the method requirements are met while minimizing the use of blind plates. Each blind plate set must be labeled as either "usually open" or "usually closed." The placement of the blind plate should be determined based on safety considerations, cutting effectiveness, and process requirements.

Blind Flanges Applications and Uses:

- Blind Flanges used in Homes and buildings

- Blind Flanges used in Transporting materials

- Blind Flanges used in the Automotive industry

- Blind Flanges used in Sewerage systems, industrial water lines, and water mains

- Blind Flanges used in heating, ventilating, and air-conditioning equipment

- Blind Flanges used in Plumbing

- Blind Flanges used in Food Processing Industry

- Blind Flanges used in Paper & Pulp Industry

Flanges Types

- Socket Weld Flanges

- Threaded Flanges

- Reducing Flanges

- Orifice Flanges

- Industrial Flanges

- Slip on Flanges

- Blind Flanges

- Lap Joint Flanges

- Ring Joint Flanges

- Spectacle Flanges

Forcible Forge Industries is a Leading Supplier of Blind Flanges in India

Forcible Forge Industries stands as India’s foremost Blind Flanges Supplier, revered for our commitment to excellence. Our superior Blind Flanges, coupled with attentive customer service and proficient in-house processing capabilities, have positioned us as a prominent and trusted supplier in India. Since our establishment in 2004, Forcible Forge Industries has upheld ISO 9001:2009 certification, underscoring our dedication to quality and reliability. Our steadfast focus on product dependability and performance has propelled us to the forefront, earning acclaim as premier providers of Blind Flanges across India.

Client Projects for Blind Flange Supplier in India

Forcible Forge Industries proudly stands as one of the premier Blind Flanges Dealers in India. Monthly, we supply our top-notch Blind Flanges to approximately sixty countries, catering to a diverse range of clientele. Over the past two decades, our unwavering commitment has seen us deliver over 3500 containers of Blind Flanges worldwide. Renowned for our reliability, our brand signifies swift delivery, competitive pricing, and unmatched quality in Blind Flanges. With a widespread presence, we have supplied Blind Flanges to numerous cities across India, earning the trust and satisfaction of our valued customers.

| Product supplied | City |

| Blind Flanges for Automobile Industry | Delhi, New Delhi |

| Blind Flanges supply | Hyderabad, Telangana |

| Blind Flanges supply for Water Supply System | Banglore, Karnataka |

| Blind Flanges for Chemical industry | Surat, Gujarat |

Blind Flanges Supplier in India

Blind Flange's consistent reliability and outstanding performance have propelled Forcible Forge Industries to the forefront as one of the leading suppliers, dealers, manufacturers, and exporters of Blind Flanges in India. Every month, we diligently supply and export Blind Flanges to Indian ports, totaling around fifty-seven containers, serving a diverse clientele.

Our commitment to delivering high-quality Blind Flanges at competitive prices, accompanied by seamless services, has enabled us to establish a strong presence across India. To better cater to our valued customers, we have deployed sales representatives in key cities, including:

| City we supply Blind Flanges | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Blind Flanges Exporter

Forcible Forge Industries proudly exports Blind Flanges to over 50 countries worldwide. Each month, we dispatch shipments to various nations to fulfill the needs of our expanding customer base. With a readily available stock of Blind Flanges, we ensure prompt delivery, meeting the demands of our customers swiftly and efficiently.

In addition to our widespread export operations, we also offer Blind Flanges to other countries, ensuring our high-quality products reach customers globally.

| Countries we supply and export Blind Flanges worldwide | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | New Zealand |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

Blind Flanges Packaging & Delivery Details

1. Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer), other

2. Port of Dispatch: Mumbai OR KALAMBOLI India

3. Packaging Details: Blind Flanges are packaged with caution and safety so they reach our client’s as good as he would expect. Packaging Charges Extra

4. Tax: 18% GST