Socket Weld Flanges Manufacturers, Supplier & Dealer in India

Forcible Forge Industries stands as a leading manufacturer of Socket Weld Flanges based in Mumbai, India. Our Socket Weld Flanges are meticulously crafted to cater to diverse piping applications across various industries, including steel factories, chemical plants, petrochemical facilities, fire protection systems, and more.

Our comprehensive range of AWWA Socket Weld Flanges encompasses a variety of materials, including Monel, Inconel, Carbon Steel, Copper Nickel, Stainless Steel, and more, ensuring suitability for a wide array of requirements. Compliant with ANSI B16.5 standards, our Socket Weld Flanges are engineered with precision and adhere to international quality benchmarks.

Moreover, we specialize in offering customized solutions such as ASTM A182 Reducing Socket Weld Flanges, tailored to meet the specific needs of our discerning customers. At Forcible Forge Industries, we are committed to delivering exceptional quality and reliability in every product we manufacture.

Socket Weld Flanges Manufacturers, ANSI B126.5 Socket Weld Flanges Suppliers, ASTM A182 Reducing Socket Flanges Stockists in India

Forcible Forge Industries proudly holds the distinction of being the world leader in Socket Weld Flanges Manufacturing. With a global footprint spanning 5 continents and serving clients in approximately 80 countries, we are committed to meeting the vast international demand for our products. Renowned for their reliability and superior quality, our Socket Weld Flanges enjoy a stellar reputation worldwide.

At Forcible Forge Industries, we prioritize building strong partnerships with our clients, treating them as valued collaborators rather than mere customers. Our dedication to customer satisfaction is reflected in our unwavering commitment to delivering top-notch products and services.

We specialize in manufacturing Socket Weld Flanges in a diverse range of shapes, sizes, and specifications, tailored to meet the unique requirements of our customers. With our comprehensive capabilities, we ensure that each product meets the highest standards of excellence, fulfilling the needs of clients across various industries and regions.

Socket Weld Flanges Specification, Grades, and Material

| Socket Weld Flanges | Specifications |

| Standards | ANSI, JIS, DIN, EN1092-1, UNI, BS4504, SABS1123, AS2129, GOST-12820 |

| Dimension | ANSI B 16.5 Socket Weld Flange, BS 1560. BS 10 Socket Weld Flange, IS 6392 Socket Weld Flange, B-2.1 NPT Socket Weld Flange, API Socket Weld Flange, DIN Socket Weld Flange, JIS. MSS SP 44 Socket Weld Flange |

| Material | ASTM A105 Socket Weld Flange, ASME A105 Socket Weld Flange ASTM A266 GR.1 Socket Weld Flange, GR.2 Socket Weld Flange, GR.3 Socket Weld Flange, GR.4 Socket Weld Flange ASTM A350 LF1 Socket Weld Flange, LF2 CL1/CL2 Socket Weld Flange, LF3 CL1/CL2 Socket Weld Flange ASTM A694 F42 Socket Weld Flange, F46 Socket Weld Flange, F48 Socket Weld Flange, F50 Socket Weld Flange, F52 Socket Weld Flange, F56 Socket Weld Flange, F60 Socket Weld Flange, F65 Socket Weld Flange, F70 Socket Weld Flange |

| Class | Socket Weld Flange 150#, Socket Weld Flange 300#, Socket Weld Flange 600#, Socket Weld Flange 900#, Socket Weld Flange 1500# & Socket Weld Flange 2500# |

| Size | 1/2” NB TO 24” NB. |

| Wall Thickness | SCH.10, 20, 30, 40, 80, 120, 160, STD, XS, XXS. |

| Form | Socket Weld Flanges – SWRF |

Grades |

|

| Stainless Steel | ASTM /ASME A/SA 213 / 249 / 269 / 312 / 358 CL. I to V – 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316TI , 316H , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H , 904L . |

| Duplex Steel | ASTM/ASME A/SA 789, 790 – UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Carbon Steel | ASTM A106 Gr. A , B & C API 5L Gr. A / B, X42 ,X52 ,X60 ASTM A 53 Gr. A/B |

| Alloys Steel | ASTM /ASME A/SA 213 / 335 / 691 – P5,P9,P11,P12,P22,P91 |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

About Socket Weld Flanges

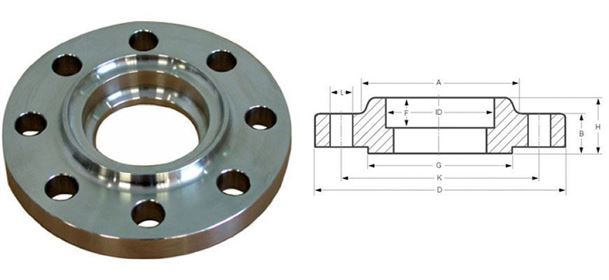

Socket Weld flanges were initially designed for applications involving small-size high-pressure piping. While their static strength matches that of Slip-On flanges, their fatigue strength surpasses double-welded Slip-On flanges by 50 percent.

These flanges are connected to the pipe via a single fillet weld on the outer side of the flanges. However, before welding, it's crucial to create space between the flanges or fittings and the pipes. This space ensures proper welding conditions and facilitates a secure connection.

ASME B31.1 1998 127.3 Preparation for Welding Socket Weld Assembly says:

In preparing the joint for welding, the pipe or tube should be inserted into the socket until reaching its full depth, and then withdrawn approximately 1/16″ (1.6 mm) from the contact point between the pipe end and the socket shoulder. This bottoming clearance serves to mitigate residual stress at the weld root that may arise during weld metal solidification.

The accompanying image illustrates the X measurement for the expansion gap.

However, a notable drawback of Socket Weld flanges is the necessity for this gap. Particularly in stainless steel pipe systems, corrosive products can lead to corrosion issues within the gap between the pipe and flanges. Consequently, in certain processes, the use of these flanges may be prohibited. While I'm not an expert in this field, there's a wealth of information available online regarding various forms of corrosion.

Advantages:

Socket weld flanges offer a viable alternative to threaded flanges, helping to minimize the risk of leakage. They eliminate the need for beveling before welding and ensure that welding occurs outside of the pipe, thus preventing penetration into the pipe bore.

These flanges are particularly recommended for applications where internal welding operations pose challenges. The socket weld construction effectively eliminates internal pockets and mitigates issues such as warpage due to welding heat and damage to the flange face caused by weld spatter.

Additionally, socket weld flanges maintain constant internal pressure as they slide onto the pipe, contributing to enhanced fatigue life compared to other types of flanges.

Disadvantages:

Indeed, welding a socket weld flange requires a higher level of skill from the welder, as they must ensure that the expanding gap between the pipe and shoulder measures precisely 1/16 inch. This meticulous process is crucial because any deviation from the specified gap size can lead to crack defects, particularly in corrosive environments such as those with stainless steel pipes. The presence of cracks between the pipe and flange can result in corrosive issues, rendering socket weld flanges incompatible with such environments.

In contrast, butt welding is often preferred in corrosive or radioactive environments. This method involves welding completely through the pipe from the outside to the inside, creating a stronger and more anti-corrosive connection. By eliminating the solid buildup at the joint that can occur with socket weld flanges, butt welding helps prevent operational and maintenance problems associated with corrosion.

Socket Weld Flanges Applications and Uses:

- Socket Weld Flanges used in Homes and buildings

- Socket Weld Flanges used in Transporting materials

- Socket Weld Flanges used in the Automotive industry

- Socket Weld Flanges used in Sewerage systems, industrial water lines, and water mains

- Socket Weld Flanges used in heating, ventilating, and air-conditioning equipment

- Socket Weld Flanges used in Plumbing

- Socket Weld Flanges used in Food Processing Industry

- Socket Weld Flanges used in Paper & Pulp Industry

Flanges Types

- Socket Weld Flanges

- Threaded Flanges

- Reducing Flanges

- Orifice Flanges

- Industrial Flanges

- Slip on Flanges

- Blind Flanges

- Lap Joint Flanges

- Ring Joint Flanges

- Spectacle Flanges

Forcible Forge Industries is a Leading Supplier of Socket Weld Flanges in India

Forcible Forge Industries stands as India’s foremost Socket Weld Flanges Supplier, revered for our commitment to excellence. Our superior Socket Weld Flanges, coupled with attentive customer service and proficient in-house processing capabilities, have positioned us as a prominent and trusted supplier in India. Since our establishment in 2004, Forcible Forge Industries has upheld ISO 9001:2009 certification, underscoring our dedication to quality and reliability. Our steadfast focus on product dependability and performance has propelled us to the forefront, earning acclaim as premier providers of Blind Flanges across India.

Client Projects for Socket Weld Flange Supplier in India

Forcible Forge Industries stands as one of the premier Socket Weld Flanges Dealers in India, earning a top-rated reputation in the industry. Monthly, we diligently supply Socket Weld Flanges to approximately sixty countries worldwide, serving a diverse clientele. Over the past two decades, our unwavering commitment has seen us deliver over 3500 containers of Socket Weld Flanges across the globe.

Renowned for our reliability and superior quality, Forcible Forge Industries is a name trusted by customers worldwide. Our brand signifies not only fast delivery and affordable prices but also an unwavering dedication to excellence in Socket Weld Flanges. With a widespread presence, we have supplied Socket Weld Flanges to numerous cities across India, solidifying our position as a trusted partner in the piping industry.

| Product supplied | City |

| Socket Weld Flanges for Automobile Industry | Delhi, New Delhi |

| Socket Weld Flanges supply | Hyderabad, Telangana |

| Socket Weld Flanges supply for Water Supply System | Banglore, Karnataka |

| Socket Weld Flanges for Chemical industry | Surat, Gujarat |

Socket Weld Flanges Supplier in India

The reliability and performance of Socket Weld Flanges have established Forcible Forge Industries as a leading supplier, dealer, manufacturer, and exporter of Socket Weld Flanges in India. Every month, we diligently supply and export Socket Weld Flanges to Indian ports, totaling around fifty-seven containers, serving a diverse clientele.

Our commitment to delivering high-quality Socket Weld Flanges at competitive prices, accompanied by seamless services, has enabled us to establish a strong presence across India. To better cater to our valued customers, we have deployed sales representatives in key cities, including: [List of cities].

| City we supply Socket Weld Flanges | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Socket Weld Flanges Exporter

Forcible Forge Industries is a global leader in the export of Socket Weld Flanges, serving customers in over 50 countries worldwide. With monthly shipments to various nations for our expanding clientele, we ensure timely delivery of Socket Weld Flanges to meet the demands of our customers.

Our extensive inventory of Socket Weld Flanges enables us to fulfill orders promptly and efficiently, catering to the diverse requirements of our clients. Additionally, we offer Socket Weld Flanges to countries beyond our regular export destinations, further extending our reach and commitment to customer satisfaction.

| Countries we supply and export Socket Weld Flanges worldwide | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | New Zealand |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

Socket Weld Flanges Packaging & Delivery Details

1. Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer), other

2. Port of Dispatch: Mumbai OR KALAMBOLI India

3. Packaging Details: Blind Flanges are packaged with caution and safety so they reach our client’s as good as he would expect. Packaging Charges Extra

4. Tax: 18% GST