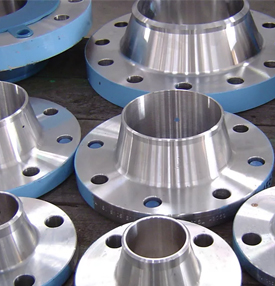

We manufacture a wide range of pipe fittings, including stainless steel pipe fittings, buttweld pipe fittings, and various forged fittings. Our offerings cover everything from elbows and tees to reducers and couplings, designed to meet diverse industrial needs.

Our pipe fittings and flanges are available in high-quality materials such as stainless steel, carbon steel, mild steel, duplex steel, and super duplex steel. We ensure that all materials meet industry standards for durability and performance.

Yes, we offer custom manufacturing for pipe fittings and flanges. Whether you need specific dimensions, materials, or unique designs, our team can create bespoke solutions tailored to your project needs.

We serve a variety of industries, including aerospace, chemical, automobile, oil & gas, petrochemicals, power plants, refineries, and sugar. Our products are designed to meet the stringent requirements of these sectors.

You can request a quote by contacting us through our website's "Request A Call Back" form or by sending an email to forcibleforge@gmail.com. Alternatively, you can call us directly at +91 93268 61773 or +91 82866 38330.

Buttweld fittings are welded directly to the pipe, creating a strong and permanent joint. Socket weld fittings, on the other hand, are designed to fit inside the pipe and are typically used for smaller sizes and pressures. Both types offer different advantages depending on the application.

Our main manufacturing facilities are located at Plot No. 273, Near Ganesh Hotel, Kolsabunder Road, Darukhana, Reay Road, Mumbai - 400010, and Plot No. B/18, Dhruv Logistics Park, Koyana Village, Panvel, Dist. RAIGAD - 410208. Our headquarters are in Navi Mumbai.

Yes, ForcibleForge is ISO 9001:2008 certified. This certification ensures that our products and services meet international quality standards and that we adhere to best practices in manufacturing and customer service.

We implement rigorous quality assurance processes to ensure that our pipe fittings, flanges, and other products meet the highest standards. This includes third-party inspections, extensive testing, and adherence to industry specifications.

Delivery times vary based on the order size and customization requirements. Typically, we aim for prompt delivery, and our team will provide you with an estimated timeframe when you place your order. We prioritize timely fulfillment to meet your project deadlines.